| A tempering chamber

suitable for liquid / vapor, liquid

/ liquid, liquid / solid / vapor and

liquid / liquid / solid measurements

under controlled conditions. Temperature

is stabilized by a user-provided circulating

bath through a unique one-loop-three-sided

thermal transfer construction in the

aluminum chamber body, which allows

desired temperatures can be reached

and stabilized exceptionally fast.

The temperature range is from about

0 ℃ to about 120 ℃ if a suitable circulating

bath and fluid are used. Due to its

double-glass window construction,

problems with window condensation

can be effectively avoided, which

ensures a clear, crisp imaging quality

for measurements .

The chamber can be easily disassembled

for cleaning purpose, suitable temperature

measurement device with RS-232-interface

and software support will also be

available as options (0.1 ℃ resolution).

Dimensions:

Chamber: 110 x 70 x 95 mm ( W x

H x D )

Glass View Windows : 30 x 30 mm

Top Opening: 40 x 10 mm ( W x D

)

Internal Measuring Space: 45 x 30

x 38 mm (W x D x H), which corresponds

to an internal volume of about 50

ml.

Dimensions can be customized within

a certain range based on the desired

applications.

For large samples or for more measurements

on one sample, the (internal) width

of chamber can be extended, for

example, for another 20-30 mm.

Electrically heated chambers can

be also provided for high temperature

ranges (up to ca.

300 ℃), An electrically heated chamber

is required for measuring polymer

and hot melts.

Surface/ Interfacial Tension Applications:

Temperature is an important factor

in-case-of surface/interfacial tension

measurements, and all tests should

be done in a well-controllable environment,

if surfactants are involved, dynamic

behaviors is to be expected (i.e.

surface/interfacial tension could

be strongly dependent of surface-aging).

In those cases it may take a long

time (minutes to hours) before the

final equilibrium or a steady-state

can be established, a pendant drop

can disappear due to evaporation

during this time, or it’s volume

decreases strongly, which will affect

the real surface composition and

thus the resulting surface tension.

It is meaningful to use the Raising

Bubble/Drop method instead of Pendant

Drop method for those situations,

that is to build a gas bubble in

a bulk solution (liquid) phase,

which raises from bottom to top.

All the necessary accessories will

be available upon request.

CMC Applications:

The most classic setup is to prepare

a series solutions of different

concentration, and then determine

their surface tension individually.

Another setup is to use the raising

bubble method: fill the chamber

with a known volume of solvent (e.g.

water) at the beginning, determine

its surface tension. And then add

a certain mount of surfactant solution

of known conc. into the solvent

(for example using our Auto Dosing

Unit), waiting for mass transferring

equilibrium, and determine the surface

tension again; and so on. It could

be a more effective arrangement

for routine CMC measurements with

double syringe system.

|

|

| |

|

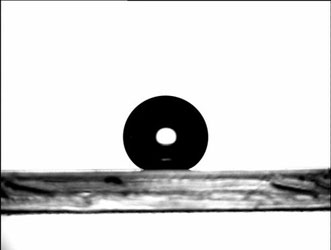

| A captive bubble

taken in the tempered chamber

(image flipped vertically) |

|